Why is that necessary?

- CSR

- Recycling of carbide tools

- Why is that necessary?

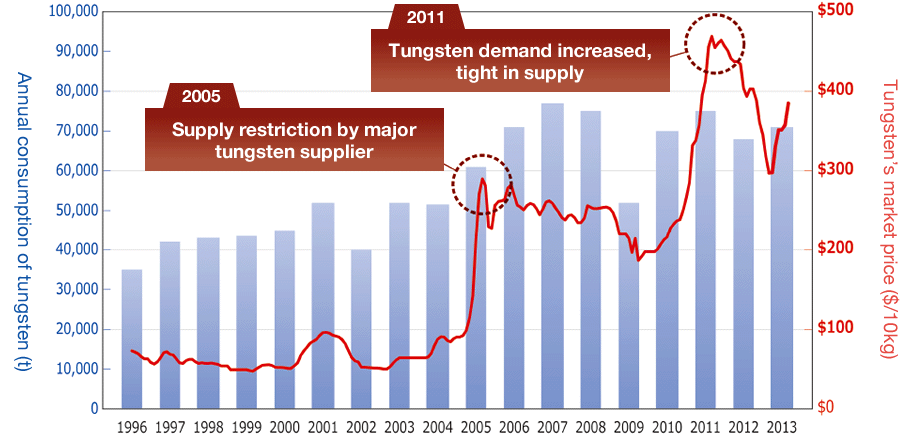

Recently, export policies in tungsten-producing countries have changed. While they were previously exporting it mainly as a raw material, with the advancement of technologies, these countries have started to consume it (and manufacture products using tungsten) domestically and in a bit to ensure domestic production, they have even gone to the extend of importing it. In addition, they have also increased its value by limiting export volumes which resulted in a sudden rise of its market price. With the worldwide consumption of tungsten increasing year by year, one of the major concerns is to have a stable supply for the future.

Efficient Refining of Tungsten

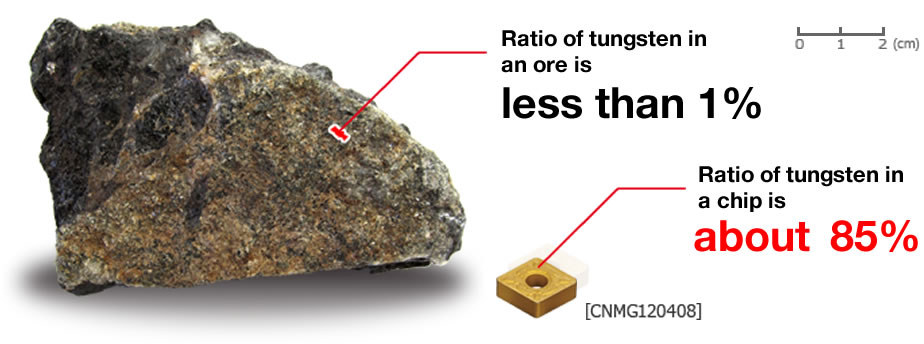

To extract tungsten from mineral, a process called "refining" is required, however, the ratio of tungsten in the mineral is less than 1%. On the other hand, tungsten content in a cemented carbide tool is approximately 85%. When the efficiency of refining is considered, you can easily understand that extracting it from cemented carbide scrap is much more "economical".

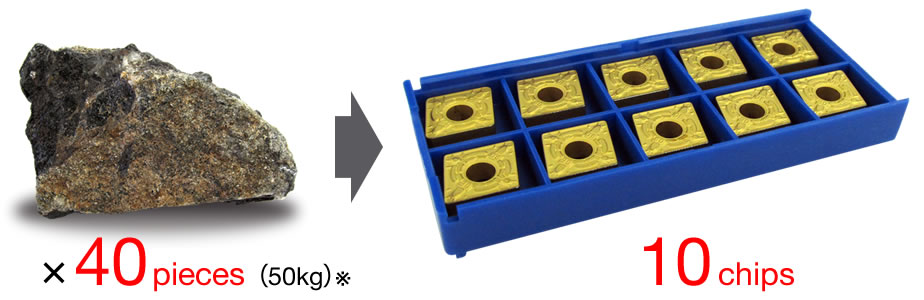

To make one insert, a volume of ores must be refined. Considering mining efforts and transportation energy, etc., you can see how economically it could be recycled from the cemented carbide scrap!

* Converted in 85% of content rate

Cemented Carbide Recycling System

Sumitomo Electric Group is ready for recycling the total volume of domestic sales of the cemented carbides internally. Allocation of raw materials domestically leads to a stable price and supply of cemented carbide tools.