General Features

Improved hardness and heat resistance with high purity ceramic binder.

Highest wear resistance among the Uncoated SUMIBORON series.

For high speed, continuous to light interrupted turning of Hardened Steel.

General Features

Significant improvements in wear and fracture resistance by using high purity ceramic binder.

General purpose grade for typical Hardened Steel turning.

For continuous to medium interrupted turning of Hardened Steel.

General Features

High density medium-grained CBN content grade with superior sharpness and wear resistance.

For high speed finishing of Grey Cast Iron.

For high efficiency machining of Powdered Metal components.

For machining of Exotic Alloys.

General Features

High density micro-grained CBN content grade with superior fracture resistance.

For finishing of Powdered Metal components with high quality surface.

General Features

Superior wear resistant substrate coupled with a special Ceramic coat for excellent wear resistance.

Optimized balance of wear and chipping resistance for high speed applications.

High speed machining of Hardened Steel of more than Vc=200m/min.

General Features

Optimized fracture and wear resistance substrate coupled with a smooth Ceramic coat.

Achieving high dimensional accuracy and excellent 1.6S surface finish.

General Features

1st Choice grade for Hardened Steel machining.

For high efficiency continuous to interrupted turning applications.

Suitable for applications with heavy cutting loads from large depths of cut.

Utilized with SV-type chipbreaker for removal of carburized layer

General Features

Extra-tough CBN substrate coupled with a highly wear resistant Ceramic coat.

Stable dimensional accuracy and surface finish even in interrupted turning applications.

Good tool life even in applications with a mixture of continuous and interrupted machining.

General Features

Significant improvements in wear and fracture resistance by using high purity ceramic binder.

World's first coated CBN grade for turning of Ductile Cast Iron.

Achieves stability under high speed conditions (Vc=400m/min and above).

Supports high precision machining with stable surface finish.

General Features

Newly developed CBN substrates and ceramic coating improve machining accuracy and tool life.

BNC2010 for high precision finish with good dimensional accuracy and surface finish.

BNC2020 for general purpose Hardened Steel machining with better stability.

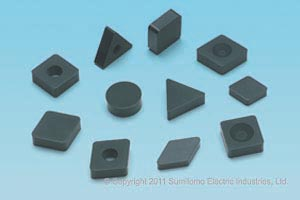

General Features

100% Solid CBN structure for high speed finishing to roughing of Grey Cast Iron.

Excellent balance of wear resistance and toughness to achieve high precision machining.

All corners of the insert, along with the whole cutting edge length, can be utilized.

Used with specially designed RM type milling cutter for high speed roughing of Grey Cast Iron.

General Features

High density ultra-fine grained polycrystalline diamond.

World's best wear resistance and strength among all PCD grades.

High efficiency and high precision machining of all Aluminum and non-ferrous alloys.

Suitable for both roughing and finishing applications.