Brands History Chapter3

- About Us

- Brands History

- Brands History Chapter3

Chapter 3: Throw-away Insert Tool Appears

-

Transition of IGETALLOY Trademark

Sumitomo's emblem "#" symbolizes the frame of a Japanese old well. Trademark "#IGETALLOY" after a "Sumitomo's emblem", which is registered in 1938. It was named after a “hanging rack”, which is Sumitomo’s symbol. It was renamed to "IGETALLOY" in October, 1959 and have been used to this date. Respectful of Sumitomo's tradition, inspiration and a spirit of challenge given in the trademark "I GET ALLOY" have been inherited until now and is the spiritual pillar of our Powder Alloy Department.

-

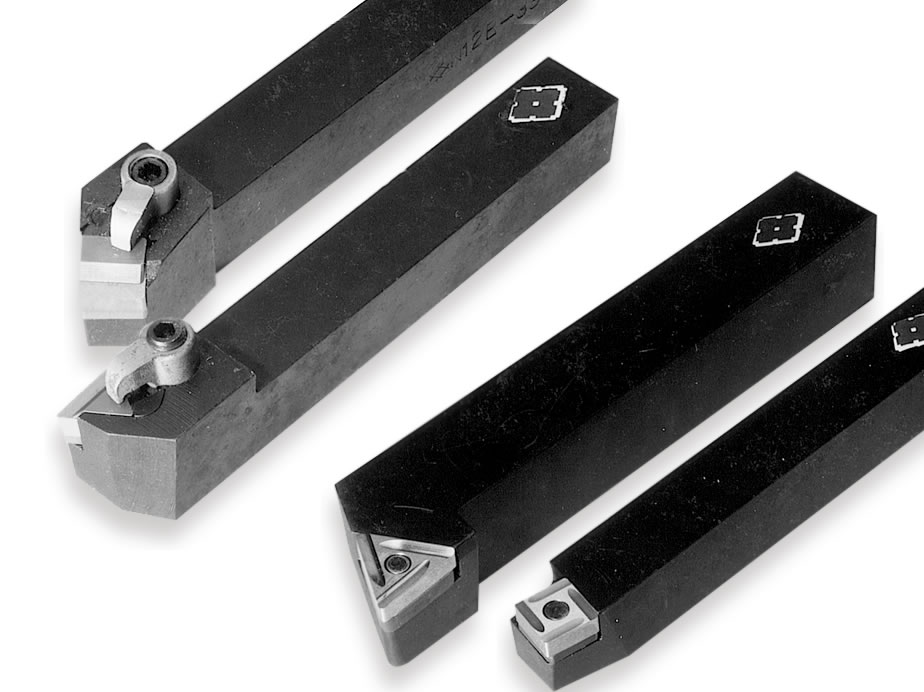

Development of SEC Tool Holders Type 20/30 Series

Using the basic "Type 3 SEC tool holder" form, the cam-lock type "SEC-30 tool holder" and clamp-on type "SEC-20 tool holder" were commercialized in 1966, based on new standards (CIS and JIS).

-

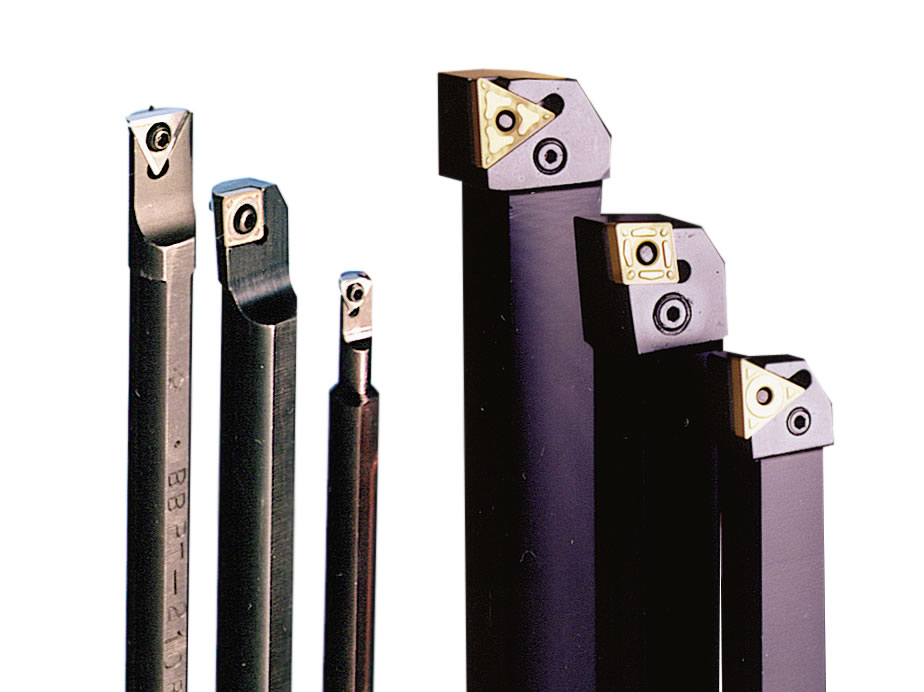

SEC Tool Holder Series

Development of the "SEC-small diameter boring bar" in 1976 and the "SEC-70 tool holder" in 1977, which conforms to the ISO standards, paved the way for the rapid progress of indexable type tools for internal and external turning tools.

-

SEC Cartridge Development

Ahead of the industry, the development of the "SEC-Cartridge BU type" in 1968 and the "SEC-Micro Unit MP type" in 1971, were recognized as compound tooling for significant reduction of machining time.

-

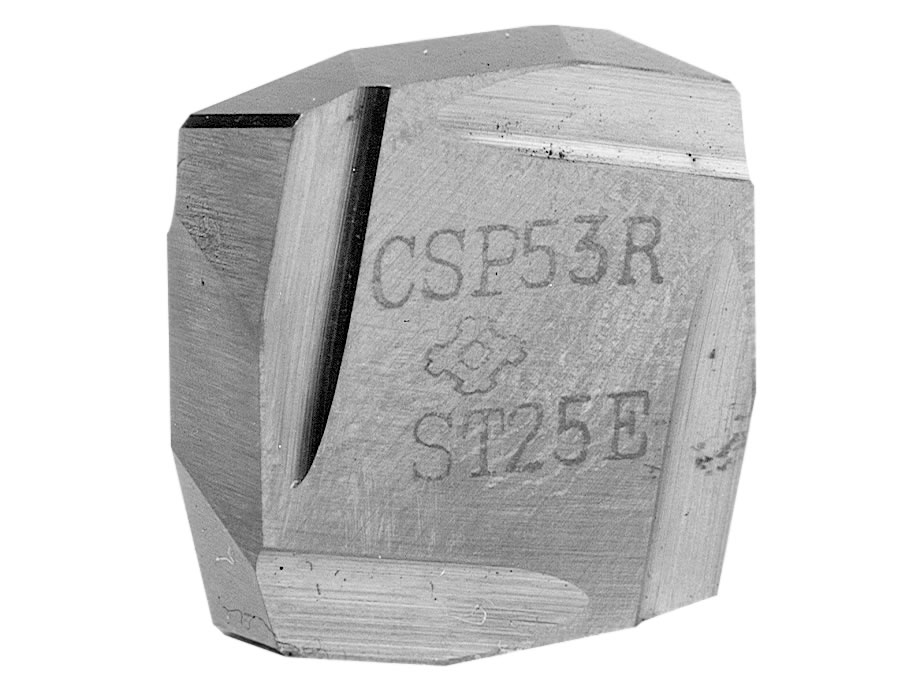

PGM Cutter Insert with Double Sheer Clear Cutting Edges (CSP53R)

-

SEC-MILL High Clear Series Takes The World by Storm

Applying the development experience of the first domestic made SEC cutter, 3 series of the unique and innovative "SEC-MILL High Clear Series" were released in July 1966. Among the series, the PGM type was the most popular and dominated the industry as a bestselling product.

-

IGETALLOY "E Series" Development

In the 1960s, IGETALLOY new "E Series" grades (ST20E / U10E / G10E) were developed in succession and were mainly used for brazed cutting tools and throw-away tips. They are also stored in the "Time Capsule EXPO70" to commemorate the Osaka Expo (in Osaka Castle Park).

-

IGETALLOY Long Roll

For the purpose of making large sized alloys, we manufactured the nation's largest cemented carbide roll (60mm diameter × 1,400mm length) using a static pressure mold (rubber press) around 1962 and received a Top Ten New Product Award from Nikkan Kogyo the next year in 1963.