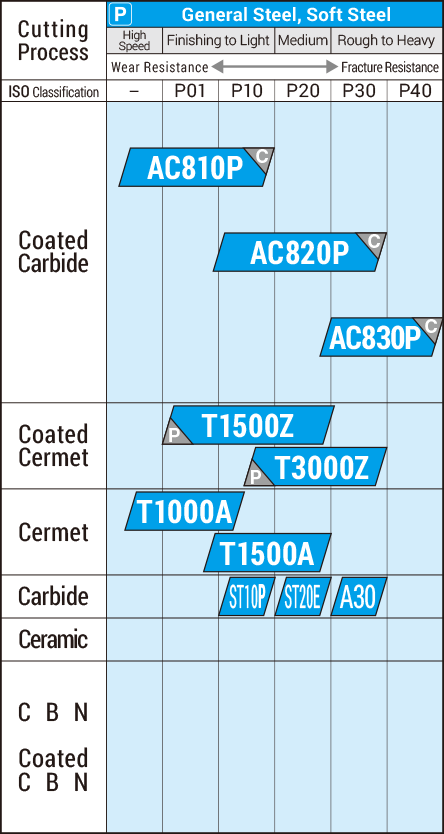

Grades Selection (Turning)

- Products

- Grades Selection (Turning)

General Steel , Soft Steel

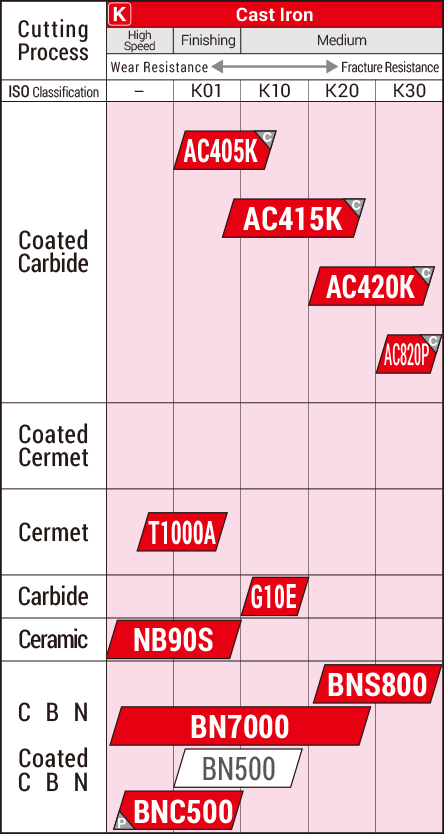

Cast Iron

Coated Carbide

AC405K

Superior wear and plastic deformation resistant grade, that utilizes a high hardness carbide substrate coupled with the high hardness Super FF Coat for high speed to continuous turning of Cast Iron.

AC415K

1st Choice grade for cast iron turning that utilizes a special carbide substrate with the high hardness Super FF Coat, to achieve stability and long tool life in a wide range of applications that includes interrupted cutting.

AC420K

Utilizing a special dedicated carbide substrate coupled with the Super FF Coat to achieve stability and long tool life for roughing to interrupted cutting of ductile cast iron and gray cast iron.

AC820P

For strong interrupted machining of ductile cast iron.

Cermet

T1000A

Cost effective, uncoated cermet grade suitable for cast iron finishing, which requires high hardness.

Carbide

G10E

Carbide grade for general turning and general milling of cast iron.

Ceramic

NB90S

Al2O3 + carbide based ceramic grade. For finishing and boring of cast iron.

CBN (SUMIBORON)

BNS800

100% solid CBN sintered compact with excellent thermal shock resistance.

BN7000

For machining cast iron and exotic alloys with improved wear and fracture resistance.

BN500

Optimized grade for cast iron machining with excellent wear and fracture resistance.

BNC500

Suitable for machining of difficult-to-cut cast iron materials with an abrasion-resistant base material and coating.

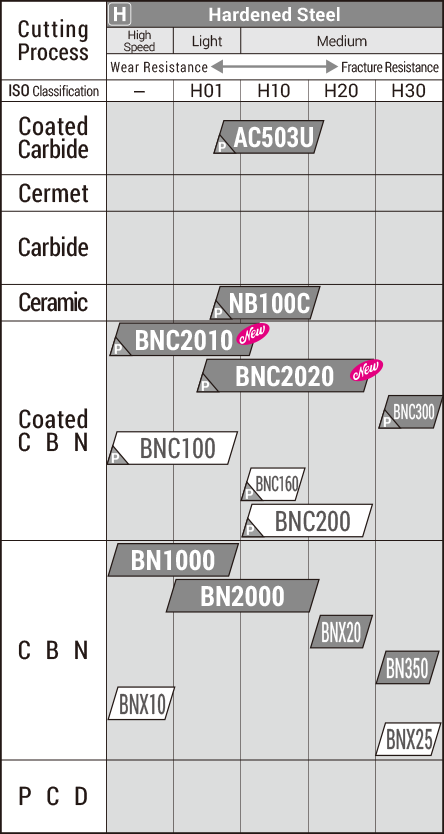

Hardened Steel

Coated Carbide

AC503U

For machining of hardened steel. Utilizing a new PVD coating with super multi-layered, nanometer thick TiAlN and AlCrN layers that provides exceptional wear resistance, when combined with a carbide substrate.

Ceramic

NB100C

Al2O3 based super-hard ceramic + ZX Coat. For low speed to light, continuous turning of hardened steel.

Coated CBN (SUMIBORON)

BNC2010

Improves the wear resistance of coating and substrate and stably achieves excellent surface roughness.

BNC2020

Provides long tool life in general and high-efficiency cutting thanks to tough substrate coated with a highly wear-resistant and adhesive layer.

BNC100

Using an excellent wear resistant coating that is suitable for high speed finishing.

BNC160

Achieving stability in high precision finishing of hardened steel.

BNC200

Boasts long tool life with a tough substrate and an excellent wear resistant coating.

BNC300

Suitable for finishing of workpieces with mixed interrupted and continuous cut portions.

CBN (SUMIBORON)

BN1000

Suitable for high speed machining with its best-in-class wear and fracture resistance.

BNX10

Wear resistant grade suitable for high speed machining.

BNX20

Excellent crater wear resistant grade suitable for high efficiency machining where cutting temperatures are high.

BN2000

General purpose grade for hardened steel machining with a good balance of wear and fracture resistance.

BNX25

Exhibits superior fracture resistance in high speed machining and is also suitable for high speed interrupted machining of hardening steel.

BN350

Providing the best-in-class cutting edge strength and is suitable for heavy interrupted machining.

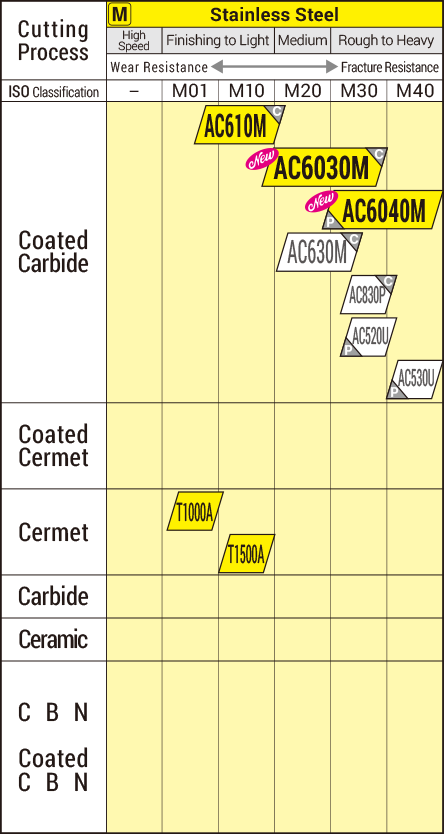

Stainless Steel

Coated Carbide

AC610M

M10 carbide grade which achieves high efficiency machining of stainless steel with improved wear resistance, by utilizing a special carbide substrate and a thin Super FF Coat.

AC6030M

General purpose grade with improved wear and fracture resistance for stainless steel machining that utilizes a tough, dedicated carbide substrate coupled with a thin Super FF Coat.

AC6040M

General purpose grade with improved wear and fracture resistance for stainless steel machining that utilizes a tough, dedicated carbide substrate coupled with a thin Super FF Coat.

AC630M

General purpose grade with improved wear and fracture resistance for stainless steel machining that utilizes a tough, dedicated carbide substrate coupled with a thin Super FF Coat.

AC830P

Utilizing a special tough carbide substrate and Super FF Coat to achieve stability and longer tool life, with increased toughness from P30 grades and wear resistance close to P20 grades.

AC520U

For interrupted machining of stainless steel. Utilizing a new PVD coating with super multi-layered, nanometer thick TiAlN and AlCrN layers that provides exceptional fracture resistance, when combined with an extra-tough carbide substrate.

AC530U

For heavy interrupted machining of stainless steel. Utilizing a new PVD coating with super multi-layered, nanometer thick TiAlN and AlCrN layers that provides exceptional fracture resistance, when combined with a fine-grained, tough carbide substrate.

Cermet

T1000A

Exhibiting exceptional wear resistance in continuous finishing processes. This cost effective and high wear resistant, uncoated cermet achieves consistent surface finishes not only in steel but cast iron and sintered alloys as well.

T1500A

New general purpose grade with an improved balance of wear and fracture resistance, providing excellent surface finish over a wide range of cutting conditions.

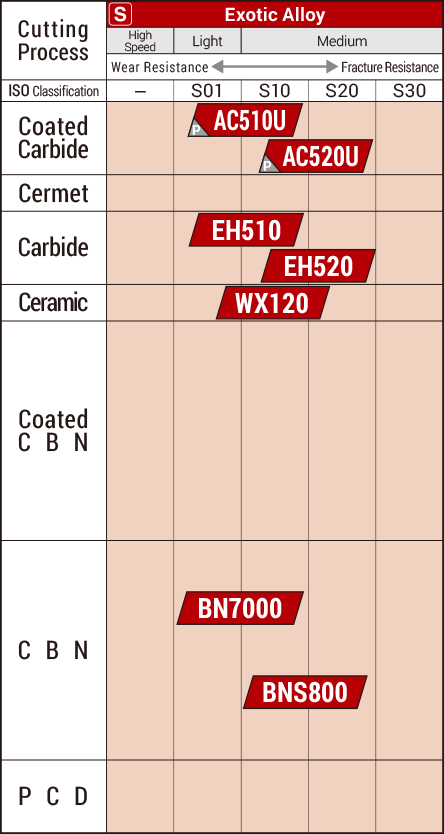

Exotic Alloy

Coated Carbide

AC510U

For finishing to medium cutting of exotic alloys. Utilizing a new PVD coating with super multi-layered, nanometer thick TiAlN and AlCrN layers coupled with a dedicated tough carbide substrate, to achieve stable and long tool life with superior wear and thermal resistance.

AC520U

For medium to roughing of exotic alloys. Utilizing a new PVD coating with super multi-layered, nanometer thick TiAlN and AlCrN layers coupled with a dedicated tough carbide substrate, to achieve stable and long tool life with superior wear and thermal resistance, even under interrupted conditions.

Carbide

EH510

Uncoated grade for continuous turning of exotic alloys. Long tool life with excellent wear and peripheral damage resistance.

EH520

Tough grade for titanium machining with excellent fracture and thermal resistance. Perfect for interrupted cutting and mill-scaled work.

Ceramic

WX120

SiC whisker reinforced ceramics. For heat-resistant alloys and hardened roll machining.

CBN (SUMIBORON)

BN7000

CBN grade with improved wear and fracture resistance, for the machining cast iron and exotic alloys.

BNS800

100% solid CBN sintered compact with excellent thermal shock resistance.

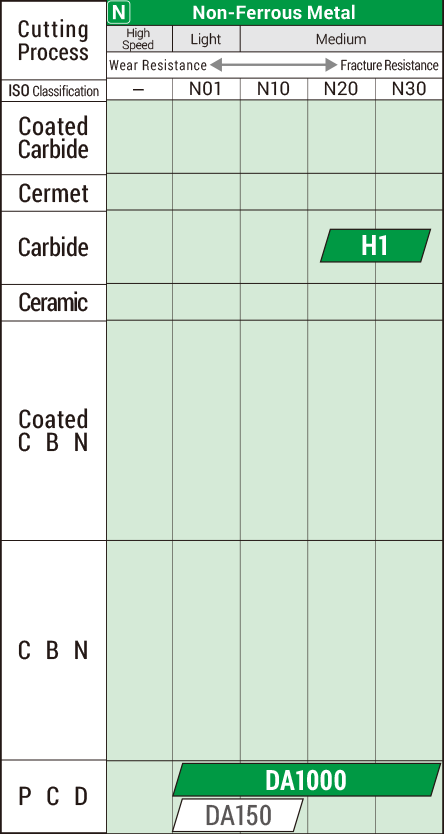

Non-Ferrous Metal

PCD

DA1000

High density, ultra fine grained sintered diamond that boasts best-in-class wear and fracture resistance, as well as excellent cutting edge integrity.

DA150

Fine grained sintered diamond that exhibits a good balance of wear resistance and workability.

Carbide

H1

Carbide grade for high speed finishing of non-ferrous metal.

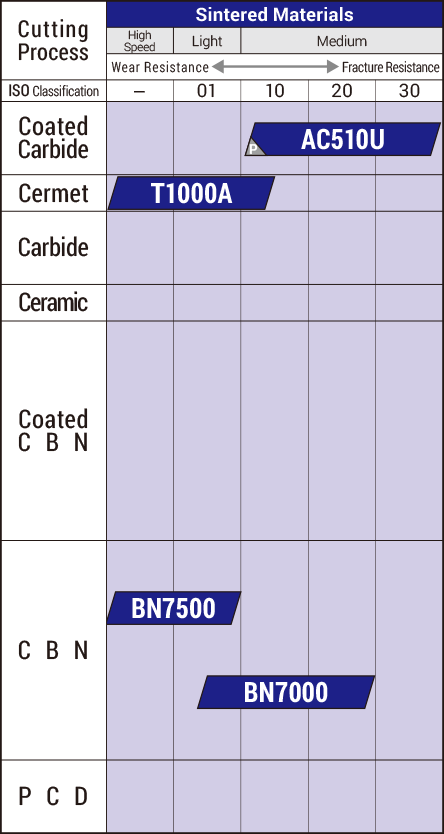

Sintered Materials

Coated Carbide

AC510U

Utilizing a new PVD coating with super multi-layered, nanometer thick TiAlN and AlCrN layers coupled with a fine grained tough carbide substrate, to achieve superior wear resistance.

Cermet

T1000A

Exhibiting exceptional wear resistance in continuous finishing processes. This cost effective and high wear resistant, uncoated cermet achieves consistent surface finishes not only in steel but cast iron and sintered alloys as well.

CBN (SUMIBORON)

BN7500

Suitable for finishing of sintered alloys due to its ability to maintain excellent edge sharpness.

BN7000

For roughing of sintered alloys with improved wear and fracture resistance.