Grades Selection (Milling)

- Products

- Grades Selection (Milling)

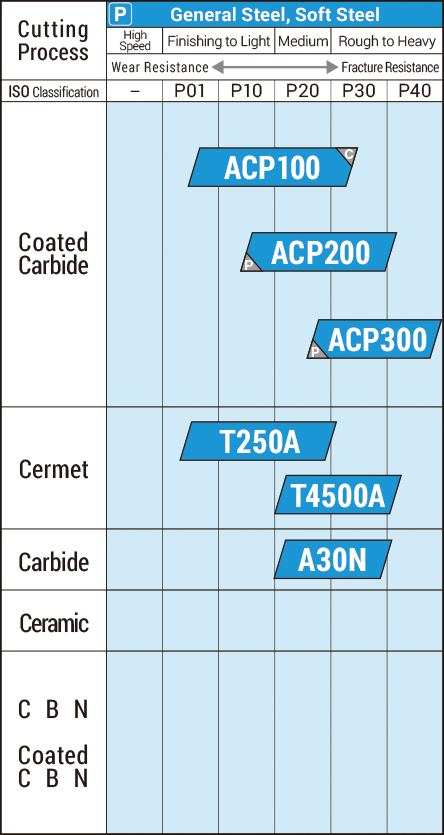

General Steel , Soft Steel

Coated Carbide

ACP100

For highspeed, wet cutting of general steel, with excellent thermal cracking and wear resistance.

ACP200

General purpose grade with excellent wear resistant Super ZX Coat, for milling of general and mold steel.

ACP300

Utilizing a super tough carbide substrate with Super ZX Coat, for roughing of general steel.

Cermet

T250A

Cermet grade that covers a wide range of work from general steel to stainless steel, with high cutting edge strength and fracture toughness.

T4500A

Excellent fracture resistant cermet that suppresses thermal cracking.

Carbide

A30N

Carbide grade for general to heavy machining of steel.

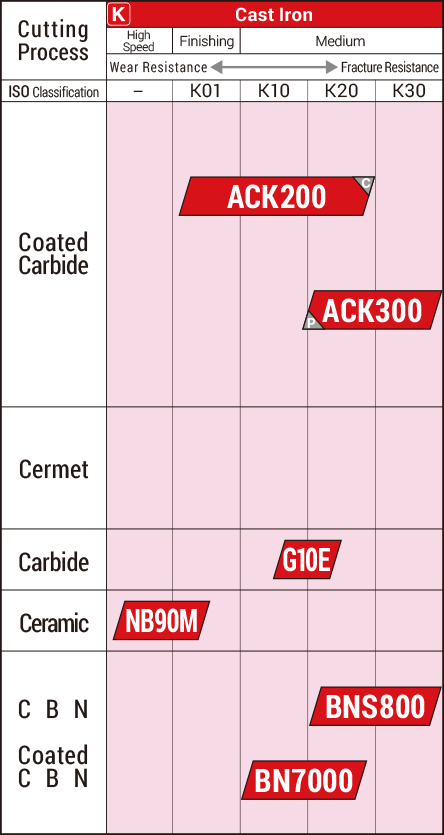

Cast Iron

Coated Carbide

ACK200

For high speed milling of cast iron, with excellent thermal cracking and wear resistance.

ACK300

Utilizing a super tough, fine grained carbide substrate with Super ZX Coat, for milling of cast iron.

Carbide

G10E

Carbide grade for general milling of cast iron.

Ceramic

NB90M

Al2O3 + tough carbide based ceramic grade. For high speed finish milling of cast iron.

CBN (SUMIBORON)

BNS800

For high speed milling of gray cast iron. 100% solid CBN sintered compact for high speed rough milling.

BN7000

For machining cast iron and exotic alloys with improved wear and fracture resistance.

BN500

General purpose CBN for continuous finishing of cast iron (FC)/hardened rolls.

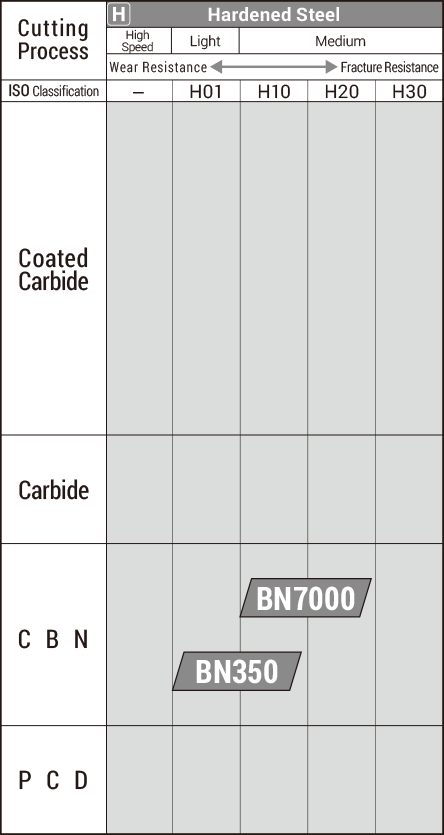

Hardened Steel

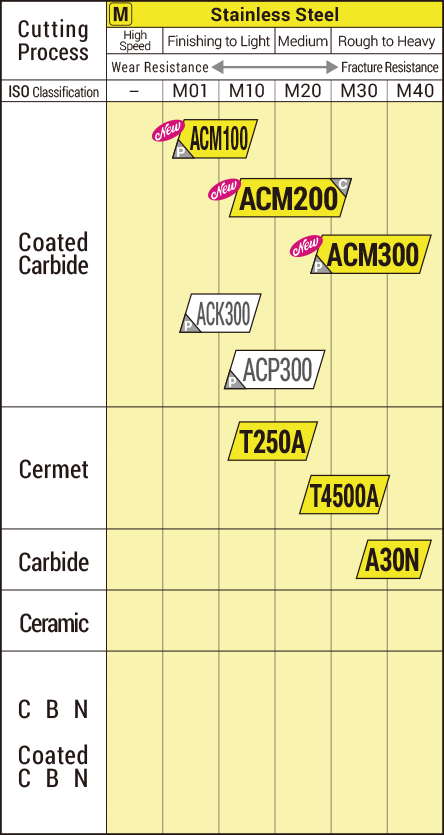

Stainless Steel

Coated Carbide

ACM100

A high efficiency M10 grade featuring improved wear resistance during stainless steel cutting. Employs special, ultra-hard substrate and thin Super FF Coat.

ACM200

A grade ideal for hardened steel machining that provides excellent wear and heat resistance by employing a newly-developed ultrahard carbide and Super FF Coat.

ACM300

A general purpose grade featuring improved wear and fracture resistance during stainless steel cutting. Utilises a special tough carbide substrate with a thin Super FF Coat.

ACK300

Utilizing a super tough, fine grained carbide substrate with Super ZX Coat, for milling of cast iron.

ACP300

For rough milling of stainless steel by utilizing Super ZX Coat for excellent wear and thermal resistance.

Cermet

T250A

Cermet grade that covers a wide range of work from general steel to stainless steel, with high cutting edge strength and fracture toughness.

T4500A

Excellent fracture resistant cermet that suppresses thermal cracking.

Carbide

A30N

Carbide grade for general to heavy machining of stainless steel.

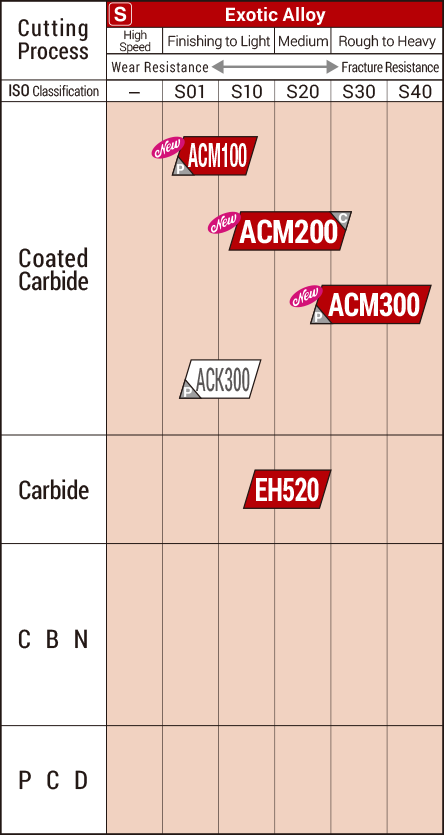

Exotic Alloy

Coated Carbide

ACM100

A high efficiency M10 grade featuring improved wear resistance during stainless steel cutting. Employs special, ultra-hard substrate and thin Super FF Coat.

ACM200

A grade ideal for hardened steel machining that provides excellent wear and heat resistance by employing a newly-developed ultrahard carbide and Super FF Coat.

ACM300

A general purpose grade featuring improved wear and fracture resistance during stainless steel cutting. Utilises a special tough carbide substrate with a thin Super FF Coat.

ACK300

Utilizing a new PVD coating with super multi-layered, nanometer thick TiAlN and AlCrN layers coupled with a tough, fine grained carbide substrate, to achieve excellent fracture resistance.

EH520

Tough grade for titanium machining with excellent fracture and thermal resistance. Perfect for interrupted cutting and mill-scaled work.

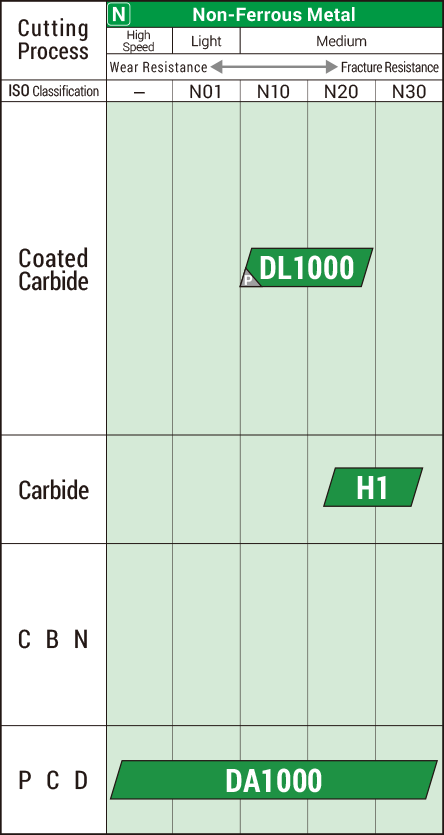

Non-Ferrous Metal

Sintered diamond (SUMIDIA)

DA1000

High toughness, ultra fine grained sintered diamond with toughness that is comparable to carbide’s, boasts its power in milling and rough milling of aluminum alloys.

Coated Carbide

DL1000

Utilizing a super-smooth, thin DLC coat with extremely low coefficient of friction, to achieve excellent surface finish of non-ferrous metals and aluminum alloys.

Carbide

H1

Carbide grade for high speed finishing of non-ferrous metal.