New Products

- Products

- New Products

NEW PRODUCTS GUIDANCE 2021-2022

Highlights of New Product Information.

The volume of 36 pages covers Sumitomo's new products.

Downloads can be found here.

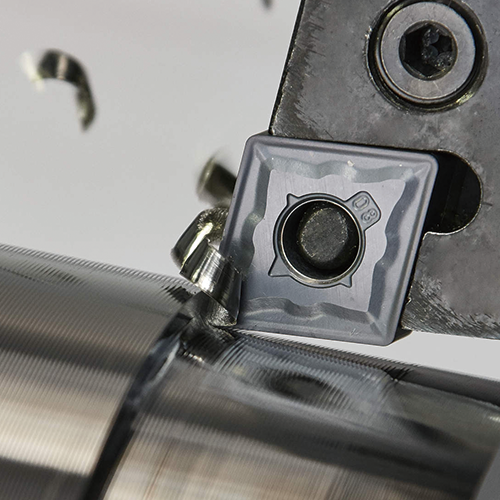

Coated Grades for Steel

AC8000P Series

For all steel turning

Realizes absolutely stable cutting in every scene from high-speed cutting to interrupted cutting.

AC8015P ▶ Ideal for high-speed machiningwith excellent wear resistance

AC8020P ▶ Newly launched. Exhibits both wear and fracture resistance in high-efficiency machining

AC8025P ▶ 1st recommended grade, with absolute reliability

AC8035P ▶ Suppresses tool breakages during interrupted cutting

Through-tool Coolant Supply Holder

SEC-External Holders DCLN-J/DDJN-J/DVJN-J/DWLN-J Type

Through-clamp internal coolant supply holder improves chip evacuation and tool life

▶ Enables directed coolant supply from a close range, towards the cutting edge

▶ Suppresses flank wear with additional coolant supply to the flank face

▶ Realises high rigidity and indexing accuracy with double clamping

Grooving / Cut-off Tools

SEC-Grooving Tool Holders GND Series

Outstanding chip control and chatter resistance

Available in 11 grades and 10 chipbreaker types, for a wide range of machining applications. Expansion of the Through-tool Coolant Holder "GNDM-J Type/GNDL-J Type" for Small Lathe.

Coolant can be supplied from the toolpost without a hose. Realising improved chip evacuation, tool life, and reduced setup time. AC8000P and AC5000S series expansion to support high-speed steel machining to exotic alloy machining

Tooling Systems

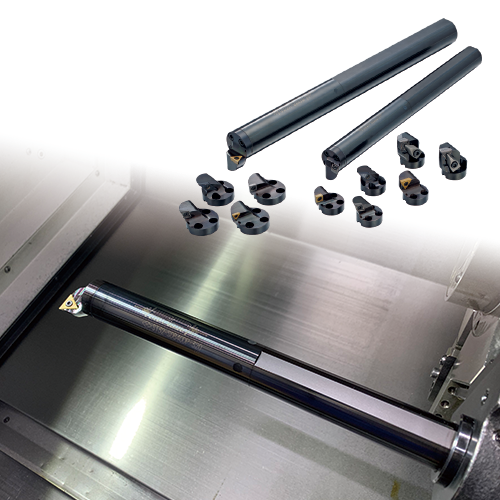

Smart Damper™ for Internal Boring

New anti-vibration mechanism offers superb vibration dampening performance

▶ Adopting a special damper mechanism to suppress chattering for large diameter holders with long overhang of L/D = 5 to 8.

▶ Replacable heads enable a wide selection positive and negative inserts.

▶ Internal coolant supply improves chip evacuation and tool life.

*Smart Damper™ is a registered trademark of BIG DAISHOWA Co., Ltd.

Coated CBN for Hardened Steel Machining

Coated SUMIBORON BNC2115/BNC2125

The Pinnacle of High Accuracy, High-efficiency Cutting

New next-generation CBN grades realise even higher-efficiency machining of hardened steel.

BNC2115 ▶ The definitive grade in high-accuracy machining

BNC2125 ▶ 1st recommended grade from high-efficiency machining to interrupted cutting

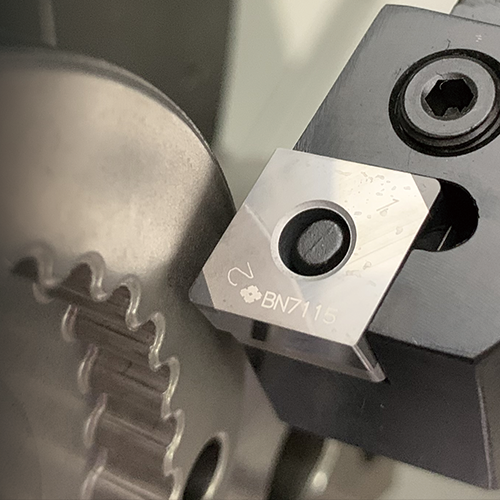

CBN Grades for Sintered Alloy Finishing

SUMIBORON BN7115

Excellent stability in high-precision finishing of sintered alloy

Enhanced bonding strength between CBN grains achieve high-accuracy, high-efficiency finishing of sintered alloy.

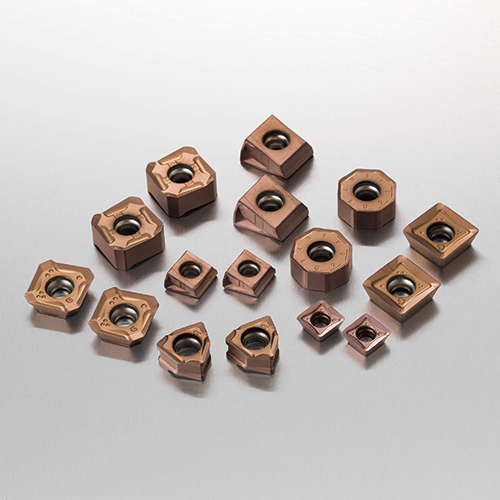

High-Productivity High-Feed Cutter for Rough Milling

SEC-Sumi Dual Mill DMSW Series

Supports ultra-high-feeds and large depths of cut

With a complex arc cutting edge shape using multiple overlapping arcs, made possible by advanced insert molding technology, higher-efficiency machining is realised.

Ramping and helical milling are also applicable, supporting various types of machining in fields including automobiles, aerospace, shipbuilding, industrial machinery, and molds.

High-efficiency and High-rigidity Radius Milling Cutter

SEC-Wave Radius Mill RSE Series

Tough cutter realises high-efficiency machining of stainless steel and exotic alloy

Designed with ultra-maximised rigidity for the insert installation seat, the durability is superb even in high-load machining.

In addition to ground type 4-cornered inserts, the lineup includes highly economical M Class 8-cornered inserts.

High-Efficiency Shoulder Milling Cutter

SEC-WAVEMILL WSE Series

Ideal for machining of titanium alloy aerospace components

Optimally designed insert cutting edge shape and high-precision insert molding technology realise high-efficiency machining and stable long tool life in titanium alloy machining.

As well, approximately twice the inclination angle is supported in machining compared to our general-purpose Shoulder Milling Cutter.

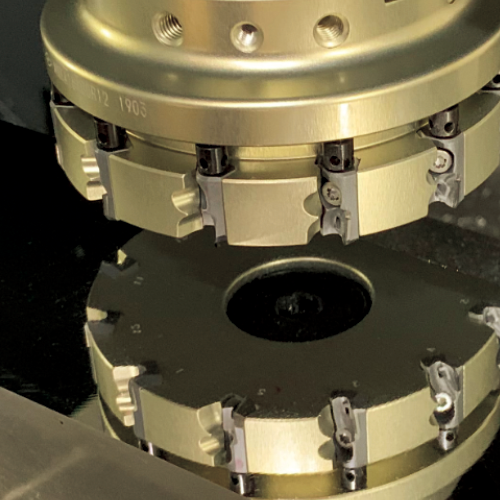

High-Efficiency Shoulder Milling Cutter for General Purpose

SEC-WAVEMILL WEZ Series

Ultra-Refined Universal Cutter

A lineup of cutters with blade diameters from ø14 to ø160mm which enable large ramping, and 28 repeater type items are now available in addition to the modular type and short shank type.

With a combination of optimised cutting edge shape and high-precision molding technology, achieves superb wall accuracy and surface finish quality.

Next-generation Nano-layered New CVD Grades

Coated Carbide Grades for Milling XCU2500/XCK2000

Achieving extremely long tool life from general to high-efficiency machining

New milling grades that utilises the next-generation "Absotech X" coating technology

A combination of wear resistance, higher than that of conventional CVD layers, and fracture resistance, comparable PVD layers

XCU2500 offers outstanding performance, regardless of cutting speed, on various work materials such as steel, cast iron, stainless steel, etc. XCK2000 realizes amazing long tool life in high-speed machining of cast iron.

High-efficiency PCD Cutter for Aluminum Alloys

ALNEX ANX Series

Achieves high-speed and high-efficiency aluminum alloy machining

By adopting Through-Blade Coolant, the coolant supply to the cutting edge is ensured and chips are separated.

Introducing a head for modular tools that supports long machining with overhang. Introducing a new CVD Single Crystal Diamond SCV10 Wiper Blade.(Modular cutter diameter range: ø25 to ø40mm)

Realises mirror finishing and large-scale burr control through sharp cutting edge. A lineup of SUMIDIA DA90 grade, enabling stabling machining.

Indexable Drill Head

SEC-MULTIDRILL SMD Series

The Ultimate in Low-cost Drilling

New indexable head MSL type is ideal for the drilling of soft steel and stainless steel.

A total of 148 items has been added, including cylindrical shanks holders with flanges.

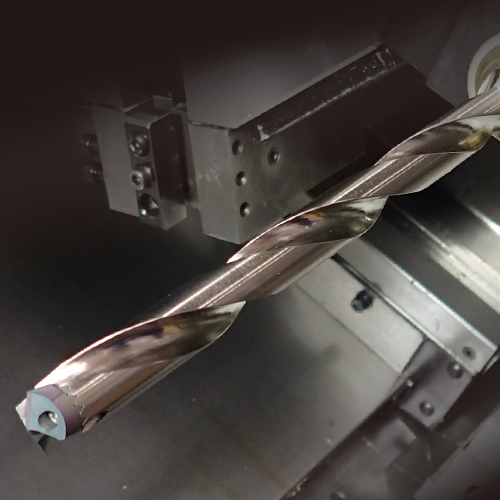

Indexable Drills

SumiDrill WDX Series

Balanced Design for Stable, High-Quality Drilling

Introducing the M type chipbreaker exclusively for stainless steel.

A choice of 4 different chipbreakers can be selected to best suit a wide variety of applications.

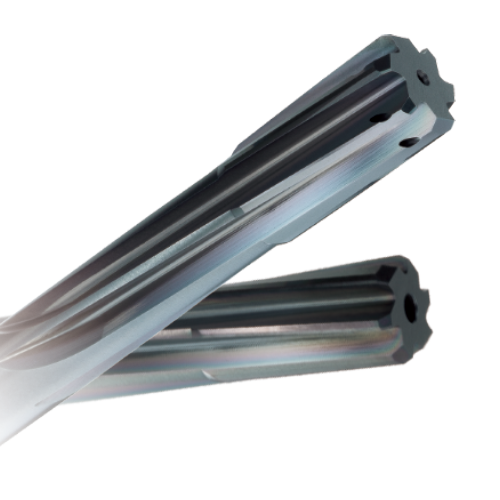

Solid Carbide Reamer

SumiReamer SSR Series

Rewriting the Book on Reamers, From Small Diameters

High efficiency and high accuracy achieved through excellent cutting edge quality and gradual right-hand helix flutes, along with a dedicated coating for reamers

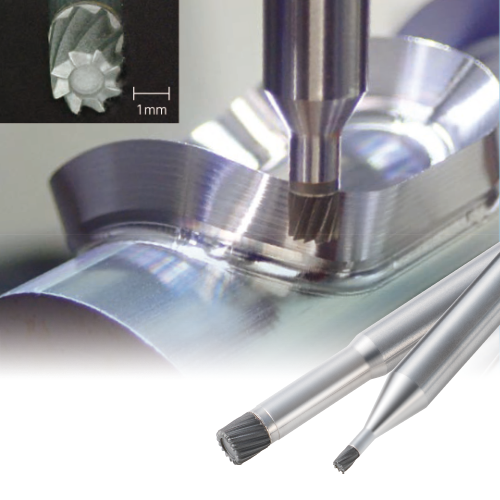

Nano-polycrystalline CBN Tools

SUMIBORON BINDERLESS Radius Endmills

Ultra-high Efficiency and Long Tool Life in Machining of Exotic Alloys and Hardened Steel

Ideal for finishing of exotic alloys like Ni-based heat-resistant alloys and mold materials for Additive Manufacturing

Excellent thermal conductivity achieves superb wear resistance.

Super multi-teeth design greatly improves machining efficiency and reduces total cost

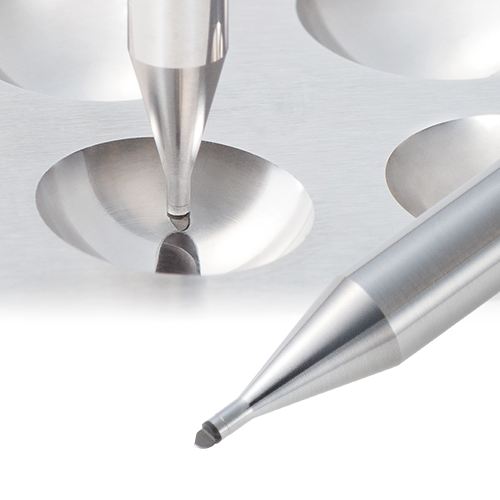

Nano-polycrystalline CBN Tools

SUMIBORON BINDERLESS Ballnose Endmills

Ultra-high precision for direct milling of hardened steel dies

Ideal for direct milling of high hardness materials such as hardened steel molds.

Maintains long-term high accuracy and excellent surface finish.